- This event has passed.

SPE APOGCE conference preview – Development of a New Oriented Perforating System for a Challenging Subsurface Environment

November 17, 2020 @ 8:00 am - November 19, 2020 @ 5:00 pm

| Paper Number | : | SPE-202391-MS |

| Paper Title | : | Development of a New Oriented Perforating System for a Challenging Subsurface Environment |

| Author Block | : | M. Haigh, A. Morrison and P. Crabtree, Chevron; F. Doombosch, Schlumberger |

APOGCE Conference 2020 registration:

https://www.spe-events.org/apogce2020/home

Abstract

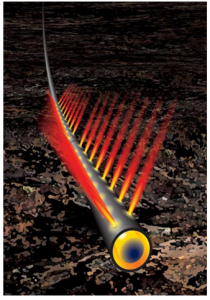

The Gorgon Stage 2 (GS2) project is a brownfield expansion of the existing Chevron-operated Gorgon Foundation Project (GFP). GS2 will maintain gas supply to the Gorgon liquified natural gas (LNG) plant by expanding the existing infrastructure with additional subsea wells in the Gorgon and Jansz-Io gas fields. Low installation risk and high life-cycle reliability were primary objectives of the GS2 well completions due to the high costs associated with subsea installation and intervention. The Gorgon subsurface environment is hostile with temperatures reaching 165°C, high concentrations of CO2 and predicted sand production. The risk to long-term sandface completion reliability is reduced significantly when the perforations are aligned toward the plane of maximum stress. To achieve the primary well objectives the GS2 project team selected shoot-and-leave, cased hole, oriented perforating (CHOP) as the Gorgon completion design.

Chevron partnered with a leading supplier of tubing-conveyed perforating (TCP) equipment to develop a highly reliable, internally oriented perforating system manufactured from corrosion-resistant alloy (CRA) material, an industry first. The development and engineering phase consisted of defining project requirements, component design, manufacture of test equipment, testing, and system integration tests. Charge testing was conducted under reservoir conditions to verify that perforating performance met minimum requirements. Other tests included verification of gun orientation accuracy at Gorgon down-hole temperatures, a significant undertaking by the TCP supplier.

Testing and qualification activities were performed at the TCP supplier’s technology center with local Chevron oversight. Quality assurance (QA) procedures were revised to be more aligned with those typically used for completion equipment, because in the industry, TCP equipment has traditionally relied on vendor-specific QA procedures and in-house oversight. Quality plans were updated to reflect the changes and enable third-party inspection (TPI) during product manufacturing. This paper will share the collaborative efforts of Chevron and the TCP supplier to design and qualify a CRA oriented perforating system and answer important questions such as “How will we build confidence that the TCP guns will orient correctly?” and “Will the perforating charges perform as required under Gorgon down-hole conditions?”