- This event has passed.

SPE APOGCE conference preview – Matrix Water Injection: A Novel Technique

November 17, 2020 @ 8:00 am - November 19, 2020 @ 5:00 pm

| Paper Number | : | SPE-202317-MS |

| Paper Title | : | Matrix Water Injection: A Novel Technique |

| Author Block | : | A. Eshtewi, R. White and S. Campbell, Woodside Energy Ltd. |

APOGCE Conference 2020 registration:

https://www.spe-events.org/apogce2020/home

Abstract

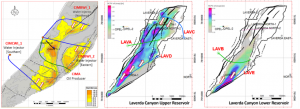

The Greater Enfield Project (GEP) is a challenging offshore oil development, designed to produce from the Laverda Canyon, Cimatti and Norton over Laverda oil fields. Six water injection wells are required to provide pressure support and sweep oil to three production wells in the Laverda Canyon and Cimatti oil accumulations to improve oil recovery. The GEP injection wells are a critical aspect of water flood design in a complex field, new to Woodside and with limited global benchmarks.

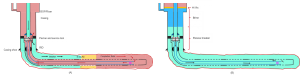

The GEP injection well design is based on a conventional water-based, sized carbonate reservoir drilling fluid (RDF) combined with a slow release filter cake breaker to deliver direct injection under matrix conditions for the field life. While filter cake chemical breakers have been extensively used in the industry, their usage is usually combined with a flowback, which is not available for GEP injection wells due to cost and the inability of some wells to naturally flow during early life. The usage of filter cake breakers to deliver sustainable direct matrix water injection is limited. Industry experience of matrix water injection is often constrained to the first few years of well life, followed by injection under fracture conditions as result of declining injectivity. This is usually related to inadequate removal of formation damage induced during the construction phase and/or a low-quality injection water.

GEP injection wells fluid system was designed to limit formation damage and provide uniform filter cake removal to maximise initial injectivity and maintain matrix injection performance for the field life (~10 years). This was achieved using a specific drilling and completion fluids (RDF, completion fluid and chemical filter cake breaker) combined with a unique clean up and displacement practices. The designed fluid system and operational practices combined with high quality injection water is expected to provide an adequate margin against injectivity decline throughout field life, with no to minimal well intervention.

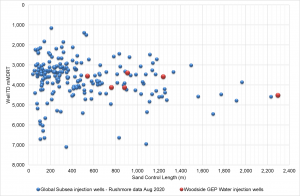

All GEP injection wells were completed in 2018-2019, one of which is globally the longest horizontal water injection well completed to date based on the Rushmore data base. Fieldwide injection commenced in July 2019 with favorable results. This paper summarises the key design aspects adopted to deliver successful matrix injection performance, presents the improvements implemented during offshore execution and provides an insight into the early life injection performance.

Figure 1: Drainage plan for Cimatti (a) Laverda CUS (a) and Laverda CLS (c) shown on a map view

Figure 2: Rushmore data for subsea injection wells

Figure 3: Woodside GEP breaker displacement schematic